The importance of the R&D Department for the KALI division

How we develop product from the KALI division? How important is the customer in this process and how important is establishing a strong partnership? We asked Dr Zagni, head of our Research & Development department, a few questions, which showed us the long growth path of a new product, such as our flame retardant MG 20-13.

Products which want to meet market needs

The KALI division supplies the market of wood semi-finished products, such as chipboard and plywood panels, providing products that can meet both facilities and regulatory needs, such as flame retardants for fireproofing, formaldehyde catchers, to reduce the volatilisation of formaldehyde, and finally glue catalysts.

We asked Dr Zagni to show us the path of a KALI product’s design and how a collaborative relationship with the customer is essential for the continuous improvement of the product itself.

“What is behind the design of a new product?"

"When you want to start a new product development, the path is articulated: usually this starts from the market, where we capture a specific need, or it starts just from one or more customers who come to ProPHOS Chemicals to find a solution to a single problem: so, it was for our flame retardant MG 20-13. From a single request we have been able to capture a need of many others, and we focused on the development of this product.

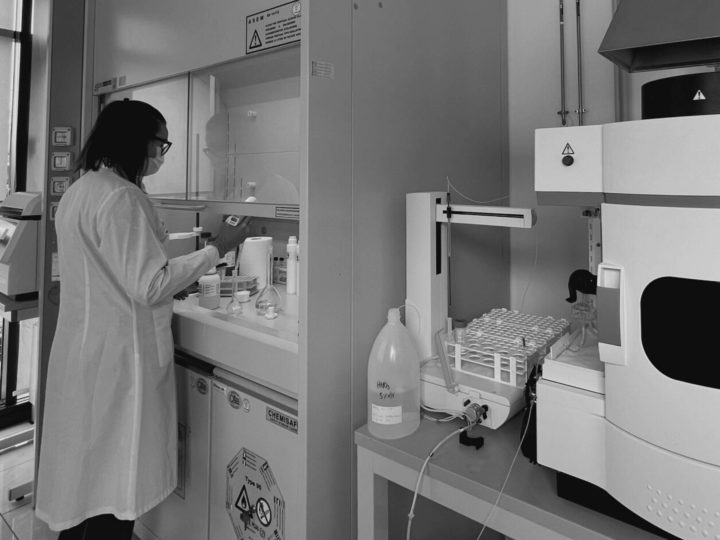

The growth of a product from the first idea up to the plant realization is a step-by-step process that involves different actors. First, the R&D department studies and examines how to realise the product, analyzing the many variables involved in the project, straight to a more concrete phase, where this study is put into practice providing the customer with some prototypes.

The contribution of our Production Department comes fundamental when we have to scale our prototypes up to our production plants: thanks to the strong know-how of our Production team, we are able to improve the formulations to create a competitive and easily reproducible product."

“

"Can we say that once scaled up the product developing ends?"

"No, the journey does not end here because once the formula has been refined and all the possible tests have been carried out, we move on to the crucial test which is conducted by the customer, who evaluates the real usability of the product and its quality. We can say that this phase is the richest in information and contents: the working relationship with our customers lead us to provide a product of guaranteed quality and, especially, a product which is suitable for each specific facilities.

It was just from these professional exchanges that the opportunity of MG 20-13 FINE arose: a new formulation with a reduced particle size distribution, focused on the "small" dimensions, able to better adapt to specific production and plant requirements, and thus to solve the problems that may come in the mixing phase, due to the size of the granule. Without a constant collaboration, we would have not reached in such a short time the opportunity of providing a high-quality solution."

“Which challenges have you met for the flame retardant MG 20-13 developing?

"Over the past few years, we have embraced the different challenges as opportunities to improve our formulas and to offer customers a high-value and high-performance product.

Through this perspective, we have first faced a path of improvement of the product in its active ingredients concentration and in its purity, thus being able to compete not only in the Italian market but also abroad with a high-quality product: a long path which has brought us many satisfactions, such as the fireproof panels certifications achieved by several customers using our flame retardant MG 20-13.

Once improved the chemical composition, we then focused on the development of the particle size distribution. Listening to our customers’ feedbacks, we found out that MG 20-13 did not perfectly fit to each production plant, so we refined the size of the granule creating our new KALI product, the MG 20-13 fine, thus satisfying a wider customer range erasing mixing problems".

"Finally, is the relationship with the customer fundamental?"

"For the KALI division, I would say it is essential.

Listening and discussing with the customers are the right terms to describe the relationship we established with them: if we do not catch our customer’s feedbacks, we would not be able to provide the best product and, at the same time, if we do not set a constructive dialogue, we could not refine it for each production change or requirement.

I could say that the close collaboration is an added value of the whole development process and realization of a KALI product, because this is what allows us to provide a product of guaranteed quality and usability".

Discover the full range of KALI products, or fill out the form for any question.